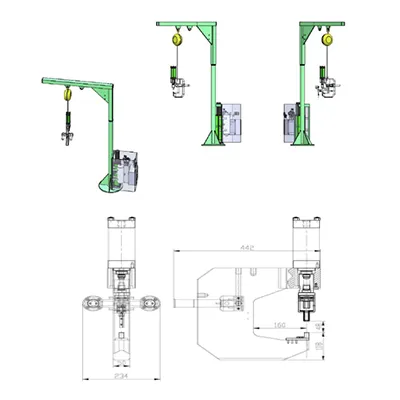

Handheld Clinching Unit, C-Frame

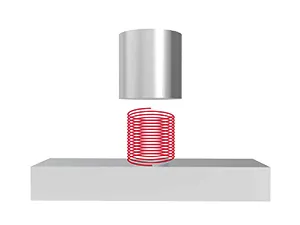

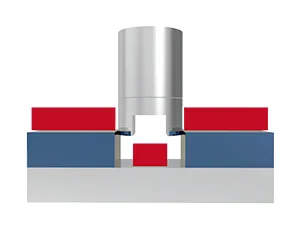

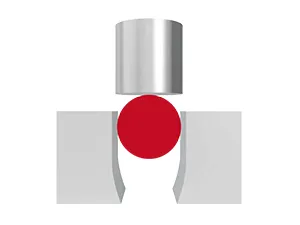

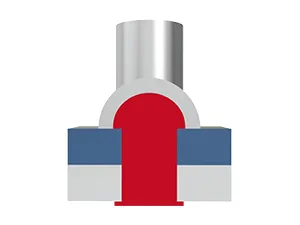

The handheld clinching unit is a manual/semi-automatic tool utilizing cold-extrusion rivetless clinching technology. By applying high pressure to two or more layers of metal sheets through the tong-head dies, it induces plastic deformation and interlocking of the sheets, forming a robust point-connection structure.

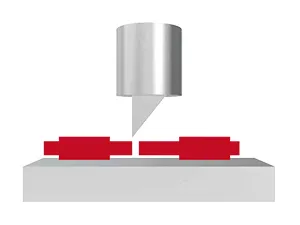

It is widely applied in the joining scenarios of metal components such as air dampers, sheet metal, automobiles, home appliances, and HVAC equipment. It is especially suitable for the rapid clinching of materials such as thin steel plates (typically 0.8-3.0 mm), stainless steel plates, and aluminum plates.

Dimensions

| Model | Max. Capacity | A | D | H | ||

| kN | T | |||||

| CRH03 | 45 | 45 | 4.5 | 28.5 | 40 | 27 |

| 45 | 45 | 4.5 | 35 | 60 | 27 | |

| 75 | 75 | 7.5 | 118 | 110 | 45 | |

| 75 | 75 | 75.5 | 118 | 160 | 45 | |

System Configuration

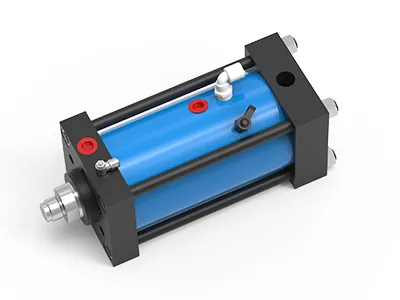

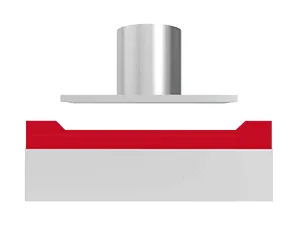

Pneumohydraulic Cylinder With Separate Working Cylinder

Pneumohydraulic Cylinder With Separate Working Cylinder Tong Body

Tong Body Intensifier

Intensifier Cantilever Bracket + Balancer (Customizable based on working conditions)

Cantilever Bracket + Balancer (Customizable based on working conditions)

Key Advantages

- High Connection Quality and Strong Structural Stability: The interlocking joint formed after clinching offers high tensile and shear strength. The joint distributes stress uniformly, resists loosening or detachment, and provides superior vibration and fatigue resistance compared to traditional rivets.

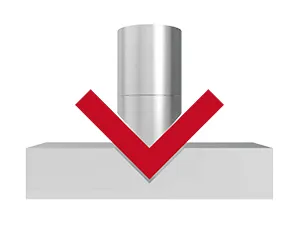

- The cold-extrusion process does not damage surface coatings (such as galvanized or color-coated sheets) or paint layers. It avoids material deformation and oxidation caused by high-temperature welding, ensuring the workpiece's aesthetic integrity and corrosion resistance, which is critical for products requiring sealing and rust prevention like air dampers and home appliances.

- Convenient Operation and Wide Adaptability: The unit is compact and paired with a suspension platform for easy operation. Designed for high-volume production, the pneumatic drive eliminates battery life constraints and ensures consistent performance throughout long shifts. Its small size and light weight allow for handheld operation without site restrictions, making it suitable for both mass production lines and on-site maintenance or high-altitude work (such as post-installation riveting for large air dampers).

- Compatible with various metal materials (cold-rolled, galvanized, stainless steel, aluminum, etc.) and sheet thicknesses (0.8-3.0 mm). Simply changing the dies allows the tool to adapt to different riveting specifications, making it ideal for damper stiffeners, sheet metal splicing, appliance casings, and other multi-scenario uses.

Applicable Processes

Forming

Forming Testing

Testing Stamping

Stamping Embossing

Embossing Drawing

Drawing Sealing

Sealing Riveting

Riveting Cutting

Cutting Bending

Bending Compression

Compression Clinching

Clinching Press fitting

Press fitting