Clinching Workbench (HVAC Damper Frame Clinching)

The damper frame clinching workbench is a specialized assembly station designed for the precision height-positioning and structural joining of air valves and fire dampers. Widely utilized in HVAC equipment manufacturing, this platform provides secure clinching for various damper sizes without requiring frequent tooling changes. Its integrated design and automated auxiliary features significantly enhance production efficiency and connection stability.

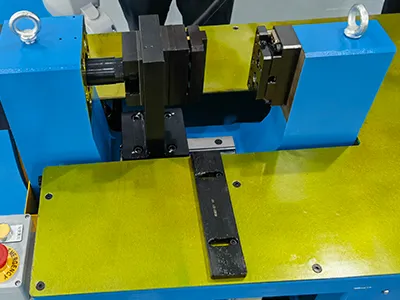

Clinching Tooling Assembly

This system includes split cylinders, intensifiers, and specialized rivet-less clinching tool sets. Each tool set is composed of the upper die, upper stripper plate, lower stripper plate, and lower die. Powered by the intensifier system, these components perform high-precision clinching on damper frames. For added flexibility, the platform can be equipped with optional suspended mobile clinching pliers (single or double-point).

Power&Control System

Driven by a high-pressure hydraulic system, the platform allows multiple operators to work simultaneously at independent stations without mutual interference. Typical configurations feature two 3 W oil pump motors, providing a total of 6kW of power. The system is managed by PLC control, utilizing individual switches and foot pedals for ergonomic operation and consistent accuracy.

Heavy-Duty Foundation

The platform is built on a stable framework with standard external dimensions of approximately 2000 × 1200 × 800mm. It can be customized with rotating brackets and auxiliary platforms to facilitate the smooth translation and positioning of various damper specifications, effectively eliminating the need for manual lifting.