Electromechanical Drive, BP Series

The BP series electromechanical drive is designed for precision press-fitting within the force range of 10-200kN. It integrates electromechanical drive with force-displacement monitoring systems to optimize the process, enhancing product quality and energy efficiency while increasing production effectiveness. The drive provides integrated process control, ensuring traceability and optimizing the production process.

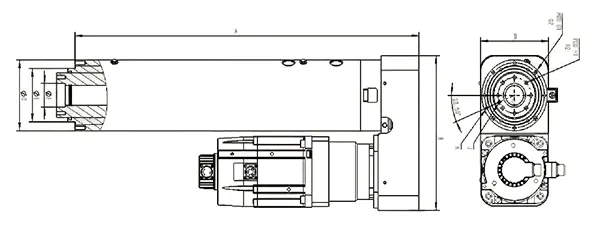

Dimensions

| Model | Stroke | A | B | C | D | E (g6) | F (G6) | G1 | G2 | H1 | H2 | J (H7) | K (H7) |

| | 300 | 680 | 250 | ⌀92 | 115 | ⌀68 | ⌀32 | ⌀84 | M5-10 | ⌀40 | M5-10 | ⌀4-10 | ⌀4-10 |

| | 300 | 776 | 285 | ⌀119 | 137 | ⌀85 | ⌀38 | ⌀108 | M6-12 | ⌀52 | M6-12 | ⌀5-10 | ⌀5-10 |

| | 300 | 862 | 345 | ⌀148 | 167 | ⌀110 | ⌀54 | ⌀135 | M8-16 | ⌀67 | M8-16 | ⌀6-10 | ⌀6-10 |

| | 300 | 938 | 390 | ⌀178 | 187 | ⌀134 | ⌀60 | ⌀163 | M10-20 | ⌀90 | M10-20 | ⌀8-15 | ⌀6-10 |

| | 300 | 985 | 410 | ⌀198 | 207 | ⌀154 | ⌀80 | ⌀183 | M10-20 | ⌀110 | M12-24 | ⌀8-15 | ⌀6-10 |

| | 300 | 1108 | 501 | ⌀228 | 241 | ⌀172 | ⌀85 | ⌀208 | M12-24 | ⌀115 | M12-24 | ⌀8-15 | ⌀8-15 |

Technical Parameters

| Model | SMT-BP-10-300 | SMT-BP-30-300 | SMT-BP-60-300 | SMT-BP-100-300 | SMT-BP-150-300 | SMT-BP-200-300 |

| Rated Pressure (KN) | 10 | 30 | 60 | 100 | 150 | 200 |

| Max. Stroke (mm) | 300 | 300 | 300 | 300 | 300 | 300 |

| Max. Speed (mm/s) | 300 | 200 | 200 | 160 | 110 | 140 |

| Repeat Displacement Accuracy (mm) | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Force Measurement Accuracy (%) | 1 | 1 | 1 | 1 | 1 | 1 |

| Rated Voltage (V) | 380 | 380 | 380 | 380 | 380 | 380 |

| Lifetime | >5 million | >5 million | >5 million | >5 million | >5 million | >5 million |

| Applicable Environment | 0-40℃ | 0-40℃ | 0-40℃ | 0-40℃ | 0-40℃ | 0-40℃ |

Software System Technical Parameters

| Channel | 1 Pressure Channel, 1 Displacement Channel |

| External Displacement Sensor | Supported |

| External Pressure Sensor | Supported |

| Data Acquisition Frequency | 10kHz |

| Low Pass Filter | 0.1-2000Hz |

| Curve Relation | Y=f(x),Y=f(t),Y=f(X),X=f(t) |

| Curve Sampling Points | 5,000,000 |

| Data Storage Records | 100000 |

| Split Screen Display | Monitors 4 presses simultaneously |

| I/O Channels | 8 inputs, 8 outputs |

| Bus Types | Profinet/Ethernet IP/EtherCAT/CClink/Modbus/CanOpen |

| Evaluation Window Type | Linear: Force limit, displacement limit, force hysteresis, displacement hysteresis Rectangle: In/out definition for four sides Envelope: Custom type, envelope tolerance type, automatically generate envelope line type, automatic recording of turning point x/y values in curve trend Multiple Evaluation Windows Integration |

Components

Servo Press

Servo Press Servo Motor Driver

Servo Motor Driver Process Monitoring Instrument

Process Monitoring Instrument Display Instrument

Display Instrument Supporting Cables

Supporting Cables

Key Advantages

- The electromechanical drive is a device that combines assembly and measurement in one. It can be integrated into both semi-automatic workstations and fully automated assembly lines with the electromechanical drive system.

- The drive effectively monitors the force and displacement during high-speed, high-precision assembly processes such as press-fitting, forming, riveting, stamping, and elastic testing.

- It helps reduce manufacturing, assembly, and inspection costs, while meeting the increasing demands for precision machining and higher manufacturing standards.

- The drive enables intelligent assembly, evaluation, optimization, and analysis, creating value for customers.

Applications

Servo press fitting is widely used in the following industries:

Intelligent Clinching Equipment for NEV Shock Tower

Intelligent Clinching Equipment for NEV Shock Tower Precision Press-Fitting&Clinching Equipment for Automotive Control Arms

Precision Press-Fitting&Clinching Equipment for Automotive Control Arms Precision Press-Fitting&Clinching Unit for Automotive Rear Subframes

Precision Press-Fitting&Clinching Unit for Automotive Rear Subframes

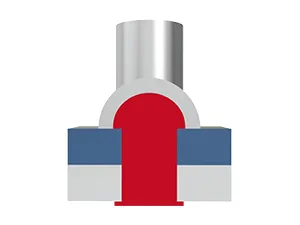

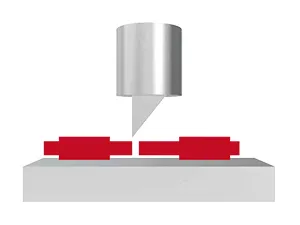

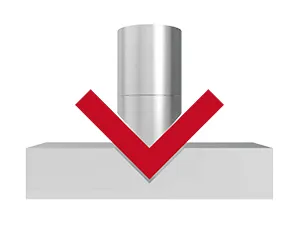

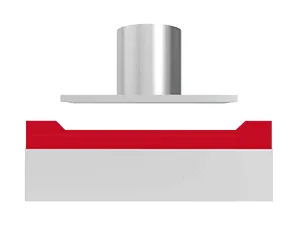

Applicable Processes

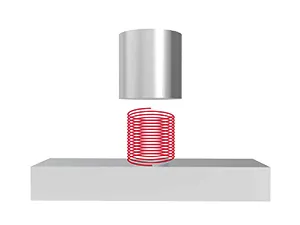

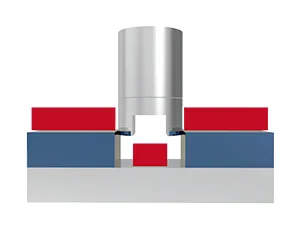

Forming

Forming Testing

Testing Stamping

Stamping Embossing

Embossing Drawing

Drawing Sealing

Sealing Riveting

Riveting Cutting

Cutting Bending

Bending Compression

Compression Clinching

Clinching Press fitting

Press fitting