Self-Piercing Riveting Machine (SPR)

The SPR Process

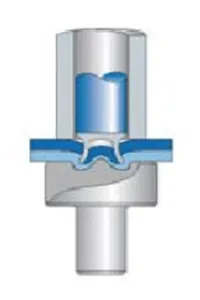

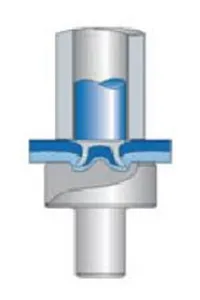

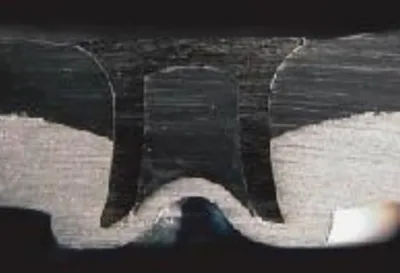

Self-piercing riveting is a cold-joining process where a rivet, driven by an external force, pierces through the upper and middle layers of material and flares out within the bottom layer. This creates a mechanically interlocked plastic deformation, forming a robust permanent joint.

These joints offer high tensile and shear strength, resulting in what is commonly known as a “lock-riveted” connection.

Main Functions

SPR is a high-efficiency riveting process that drives a rivet directly into the metal under pressure, eliminating the need for pre-drilled holes or manual rivet placement.

A self-piercing riveting machine (SPR Equipment) can automatically complete the entire cycle including loading, positioning, and riveting in under 2 seconds.

SPR is a cold-joining process. Using a specialized semi-hollow rivet under high pressure, the rivet directly pierces the upper layer and expands within the lower layer to form a mechanical interlock. This creates a secure bond across multiple layers of material.

Key Advantages

No pre-drilling required; punching and riveting are completed in a single step.

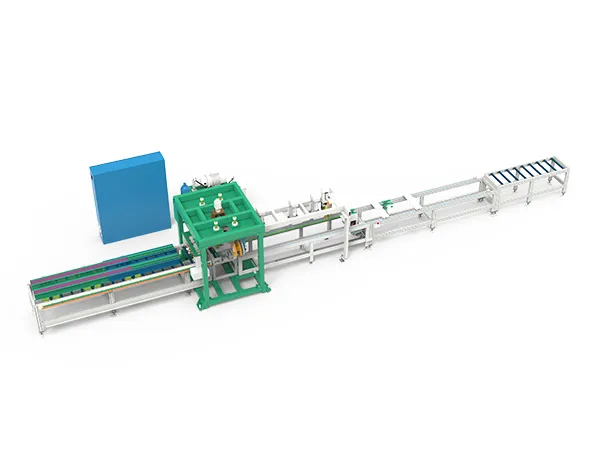

Composition of SPR Equipment

A complete SPR system is a complex, high-end integration of mechanical, electrical, and hydraulic components, consisting of:

- C-frame/Gantry Riveting Machine: Provides the massive force required and houses the riveting punch and die.

- Hydraulic Power Unit: Delivers precise, powerful pressure and control to the system.

- Automatic Feeding System: Extracts rivets one-by-one from the magazine and transports them via tubing to the riveting nozzle.

- Specialized Tooling:

①Upper Die (Punch): Presses against the rivet head to apply force.

②Lower Die (Anvil): The core of the technology; its cavity shape determines how the rivet tail expands within the bottom material to form the interlock. - High-Precision Control System: Typically based on an industrial PC or high-end PLC to accurately manage pressure, displacement, and velocity while monitoring the quality of every joint in real-time.

Advantages of SPR Equipment

- High Efficiency: Eliminates the need for pre-drilling or punching, enabling high-speed automated production with cycle times as short as 1-2 seconds per point.

- Dissimilar Material Joining: Its greatest advantage is the ability to perfectly join different materials (steel, aluminum, plastics, composites) without creating brittle intermetallic compounds like welding, solving key pain points in EV and multi-material body manufacturing.

- High Quality&Traceability: Forms a high-strength mechanical interlock with excellent fatigue resistance. The system records force-displacement curves for every riveted joint, allowing for 100% online quality monitoring.

- Environmentally Friendly: A clean production process that produces no smoke, dust, sparks, or thermal deformation.

- Superior Sealing: The resulting riveted joint is naturally airtight and watertight, enhancing the sealing integrity of the assembly.

The SPR elevator automatic riveting system is an automated self-piercing riveting unit specifically engineered for elevator structural components, such as car enclosures, door panels, and frames. By replacing traditional welding and bolting methods, it enables high-efficiency, zero-deformation, and highly consistent automated joining of elevator sheet metal. This SPR process significantly enhances both structural safety and overall production efficiency.

The SPR busbar self-piercing riveting system is an automated riveting unit specifically designed for the high-efficiency joining of busbars and copper bars. By utilizing an automated, highly consistent self-piercing riveting process, it replaces traditional bolting or welding methods to improve connection reliability, production efficiency, and process standardization.

Main Applications

Efficient joining of copper and aluminum busbars within power cabinets, NEV battery packs, and various power distribution systems.

Process Steps

Positioning

Positioning Clamping

Clamping Pressing

Pressing Piercing

Piercing Deformation

Deformation Forming

Forming

Self-Piercing Riveting Materials and Applications

The versatility of self-piercing riveting is reflected in the wide variety of rivet materials, shapes, hardness levels, and coatings available. It is highly effective for joining dissimilar materials:

Steel: 1.0mm

Steel: 1.0mm

Aluminum: 1.2mm

Steel: 1.0mm

Aluminum: 1.2mm

Aluminum: 3.0mm

Aluminum: 3.0mm

Aluminum: 1.2mm

Magnesium: 1.5mm

Plastic: 2.0mm

Aluminum: 2.0mm

Plastic: 3.0mm

Aluminum: 3.0mm

Aluminum: 1.2mm (with structural adhesive)

Aluminum: 2.0mm