The precision assembly press is an advanced automated system that integrates high-precision force control, displacement monitoring, and real-time data analysis.

Core Functions

The assembly press is designed to press-fit precision components including bearings, gears, bushings, and pins, into designated positions with programmed force and velocity. This ensures accurate interference fits through constant or variable parameter control.

Main Applications

This press is widely utilized in sectors with strong assembly standards, including:

- Automotive: Electric motors, transmissions, and NEV EIC system (battery, motor, controller).

- Industrial Precision: High-precision reducers, pumps, and valves.

- Appliances: Motors for domestic appliances.

-

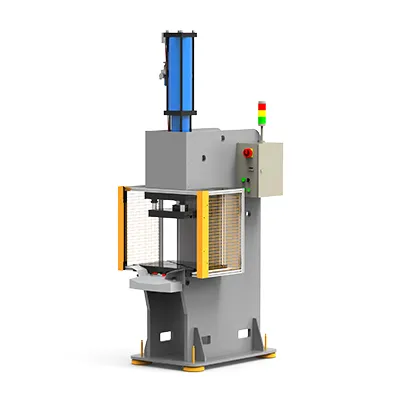

- C-frame Press, 78 - 990 KN

Press dimension and parameters can be tailored to specific customer product requirements, maximum capacity available up to 100 tons.

- Pressing Force: 78-990kN

- Power Stroke: 5-52mm

- Total Stroke: 100/200/250mm

-

- 4-column Press, 38 - 735 KN

- Structural Stability: The four-column guiding system ensures smooth operation and high precision.

- Hydraulic Drive Performance: Adjustable pressure and speed profiles provide high adaptability.

- Modular Safety: Equipped with standard safety devices and flexible functional expansion options.

-

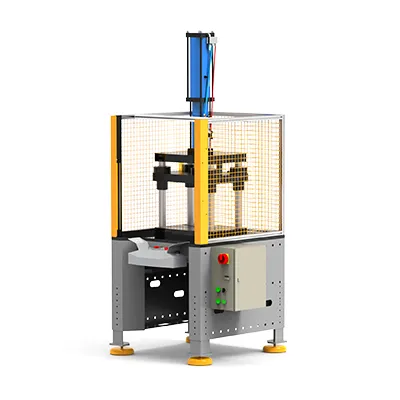

- 2-column Press, 38 - 735 KN

- Open C-frame Design: Supported by two columns with the front and sides open, providing easy material feeding and unobstructed mold observation.

- Rapid Response: Typically utilized with mechanical or compact hydraulic drives, making it ideal for medium-to-high speed blanking and shallow drawing.