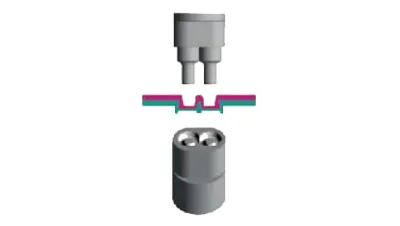

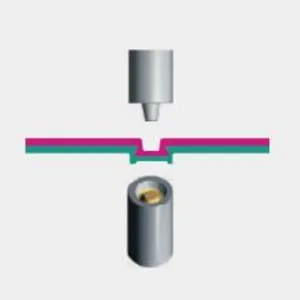

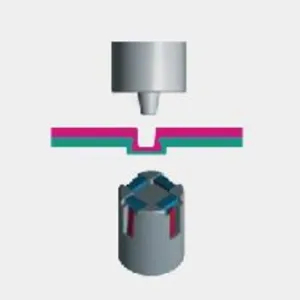

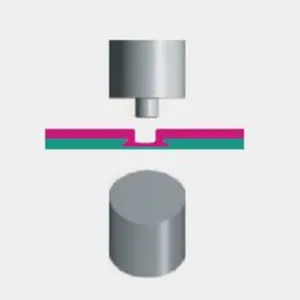

Clinching is a mechanical joining process that utilizes the plastic deformation of the sheet metal itself. By embedding the upper and lower layers into each other, a mechanical interlock (as shown in the cross-section below) is formed without the need for additional fasteners.

Compared to traditional joining technologies, clinching offers significant advantages including lower equipment costs and higher energy efficiency. The process eliminates the generation of chemical pollutants, ensuring an environmentally friendly operation that is easily integrated into automated production lines. Furthermore, clinching maintains low sensitivity to sheet surface quality, making it ideal for joining materials with coatings or protective layers. As a result, it has become one of the most critical technologies for the assembly of lightweight sheet metal components.

Round Clinching

Round joint typically formed through the compression of a standard or rotating punch.

Square Clinching

Square or rectangular joint formed using a square punch or through intermittent control of a rotating punch.

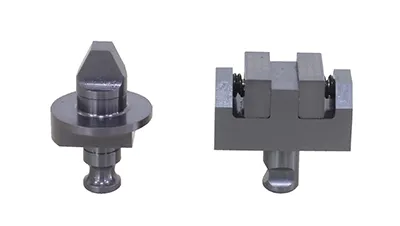

Twin-point Clinching

Two joining points formed in a single stroke. Compared to a single round joint, shear strength can be up to twice as high, and tensile strength can increase by over 1.5 times.

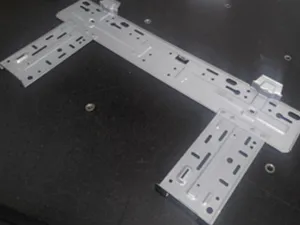

Precision-Clinched Products & Components

Micro-Point Clinching

Micro-Point Clinching Round Clinching (Clinching Die With Fixed And Movable Segments)

Round Clinching (Clinching Die With Fixed And Movable Segments) Flat Clinching (Clinching Die With Fixed And Movable Segments)

Flat Clinching (Clinching Die With Fixed And Movable Segments) Solid Round Rivet Clinching

Solid Round Rivet Clinching Rectangular Clinching with Cutting

Rectangular Clinching with Cutting Specialized Die Clinching (with 3 Movable Segments)

Specialized Die Clinching (with 3 Movable Segments)