Self-Piercing Clinch Press (SPAC)

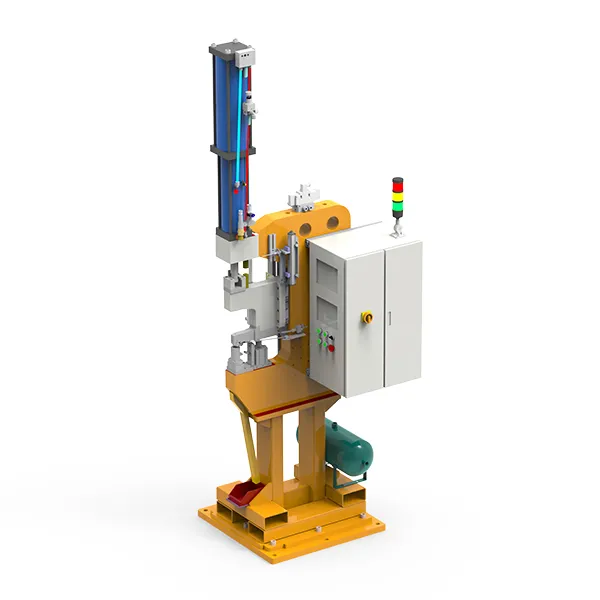

The press-riveting assembly machine is an integrated system designed for the automated assembly and interference fitting of precision components.

Main Functions

This assembly machine ensures high consistency and zero-damage press-fitting for critical components such as bearings, bushings, and gears. It is engineered to enhance overall product reliability and advance the level of assembly automation within the production line.

The automated press-riveting assembly machine is a sophisticated assembly system that integrates high-precision force control, displacement monitoring, and real-time data analysis.

Main Functions

The system is engineered to press-fit precision components, such as bearings, gears, bushings, and pins into specified positions with programmed force and velocity. This ensures an exact interference fit through rigorous parameter management.

Main Applications

This press is widely utilized in sectors with strong assembly standards, including:

- Automotive: Electric motors, transmissions, and NEV EIC system (battery, motor, controller).

- Industrial Precision: High-precision reducers, pumps, and valves.

- Appliances: Motors for domestic appliances.

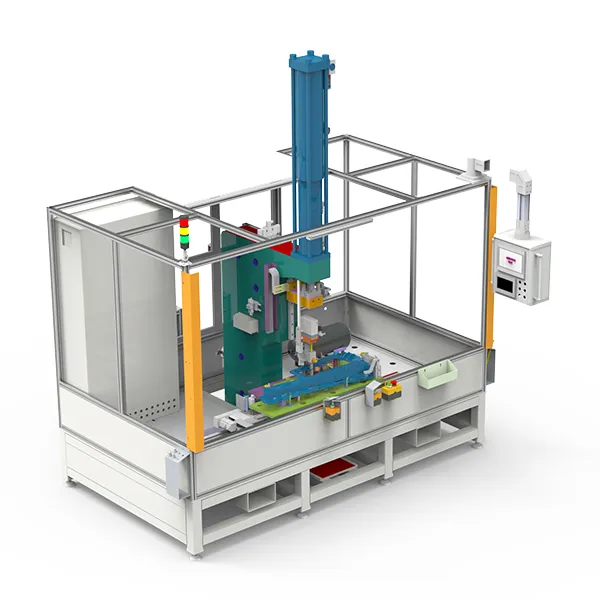

The self-piercing and clinch press is a specialized system designed for the automated clinching of automotive front frame rail assemblies. It primarily handles the joining of the frame rail body with reinforcement plates, brackets, and other critical accessories. This press is engineered to enhance the joint strength and consistency of front rails while simultaneously optimizing production cycle times. It provides essential support for automotive lightweighting initiatives and safety performance requirements.

This specialized self-piercing and clinch press is designed for the high-precision joining of car chassis or frame longitudinal members with their connecting plates. It ensures high-strength, consistent riveting of critical structural junctions, significantly enhancing chassis rigidity, vehicle safety, and production throughput.