The Challenge

GREE faced significant bottlenecks in their air conditioner back panel assembly, specifically regarding the high-precision alignment of complex multi-component structures. Traditional riveting methods resulted in low throughput and inconsistent quality. The objective was to implement a smart, mixed-model production line capable of handling diverse product variants with minimal downtime.

SIMITCH Solutions

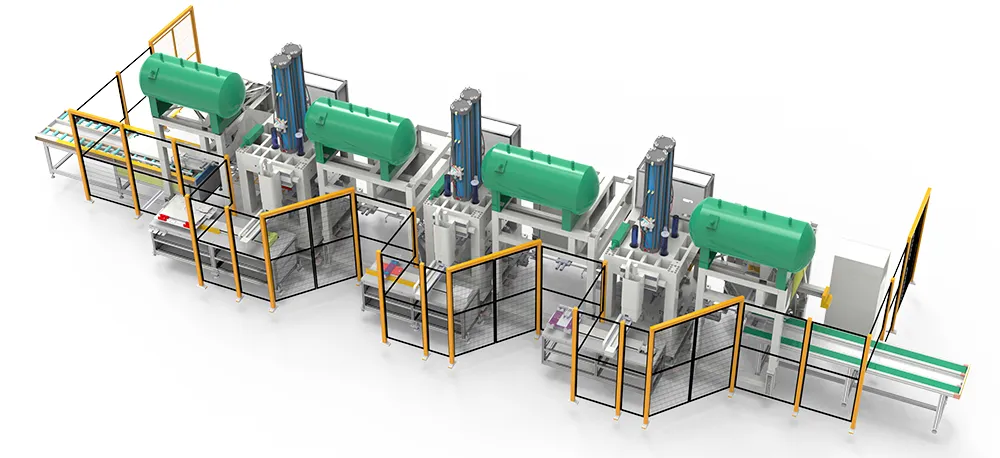

SIMITCH engineered a turnkey, fully automated production line featuring:

Intelligent Assembly

Integrated robotic loading with advanced machine vision for micrometer-level alignment of diverse sheet metal components.

High-Throughput Riveting

A multi-unit synchronous riveting system that saves takt time by 300%.

Agile Changeover

Modular tooling and programmable logic enable rapid model transitions in under 5 minutes, maximizing production uptime.

Data-Driven Quality Control

Real-time monitoring and synchronization with the Manufacturing Execution System (MES), ensuring 100% digital traceability for every joint.

Results

- Labor Efficiency: Achieved a 60% reduction in headcount by replacing manual stations with full automation.

- Production Capacity: Increased overall production efficiency by approximately 2.5 times.

- Quality Consistency: Drastically improved riveting precision, leading to a significant reduction in product defect rates.

- Strategic Value: Provided essential hardware and data infrastructure for GREE’s “Smart Factory” demonstration project.

“This automated riveting line is exceptionally stable and reliable. It has effectively addressed the long-standing efficiency and quality pain points in our back panel production, making it a critical asset in GREE’s intelligent manufacturing ecosystem.”